Hydraulic Type Die Cutting Machine With Sliding Table Feeding

Categories : Cutting Machines

Four column of hydraulic cylinder, average cutting force. Microcomputer controller for maximum operation convenience. High speed sliding table feeding, motion is fast and safe. Safety sensor is equipped in front of cutter, (when sensor is touched, the machine automatically stops the action). Application:Special design for die cutting one layer or several layers of such material as rubber sheet, leather, plastic, foam, nylon, paper board and synthetic material. yicheen

High Precision Die Cutting Machine with CCD auto position system

Categories : Cutting Machines

Application:Optical film, Plastic film, e.g.: ITO, Diffuser, Reflects film, Brightness Enhancement Film (BEF), Soft PCB, Composite material. The material are not cracked while cutting. yicheen

High Precision Die Cutting Machine (Full Electrical, One Sheet Feeding)

Categories : Cutting Machines

Application:High precision die cutting machine (Full electrical, one sheet feeding) yicheen

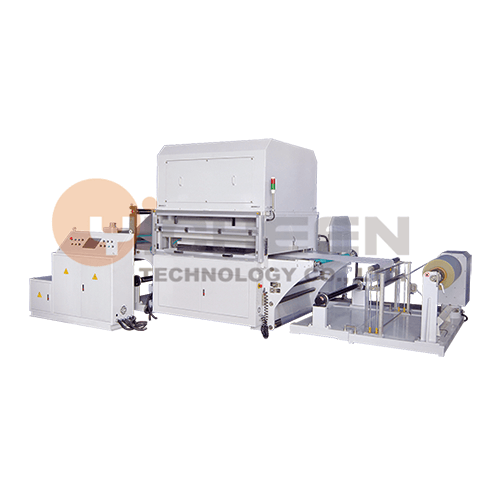

High Precision Hydraulic Type Die Cutting Machine

Categories : Cutting Machines

Application:Plastic films, such as diffuser, reflects sheet, brightness Enhancement Film, PET, PE, PVC, Paper, Self-adhesived label…etc. yicheen Max. cutting square is 1500x1500mm. PLC computer touch-panel screen control system – clear & easy in operation. Equipped with high precision mold high fine adjustment control, Four-columns can be micro-adjusted independently by computer setting parameter, to save time and to raise the production rate. Precision die cut position matching; save time & accurate in die cut mold replacement. Die mold less worn, Long lifetime in use. Also, Optional equipped with knife mold rotative mechanism, it makes the knife mold replaced convenient. Equipped with sticky mechanism, it can effectively clear dust/shavings after cutting. Optional equipped with Static eliminating device and board cleaner. Equipped with safety shelf and safety sensor on each size of machine in order to avoid any dangers while operation. Optional mechanisms: Rewind stacking system, Unwind system (shelf system or shelfless system).